- Products

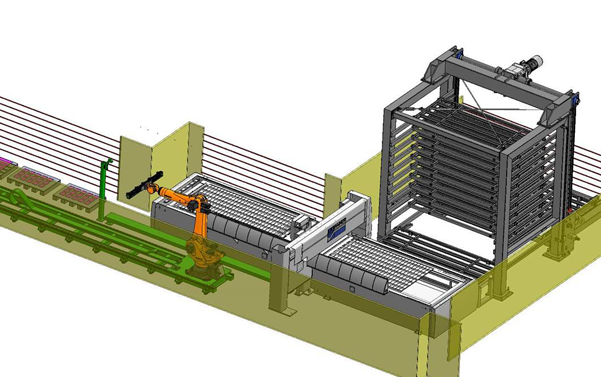

- Robotic Bending Cell

- Customized production line

- LAG Press Brake

- Fastener Insertion machine

- Rainer Punch Press

Home

>

Products

>

Customized production line

Home

>

Products

>

Customized production line

021-3900-3785

021-3900-3785

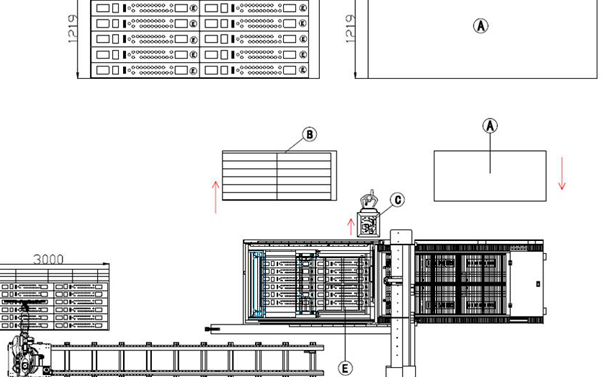

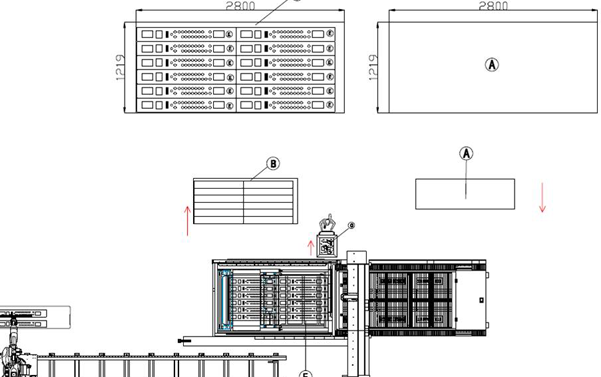

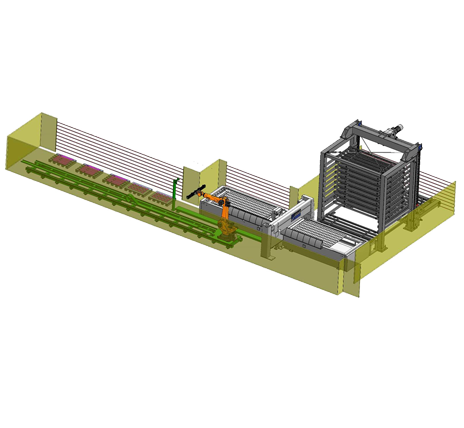

Separation scheme of thick plate laser

Returns a list of

Returns a list of

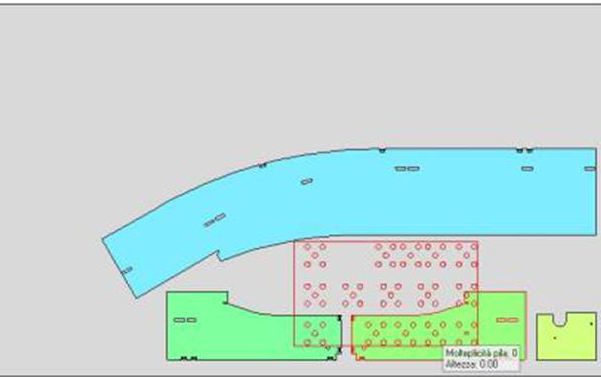

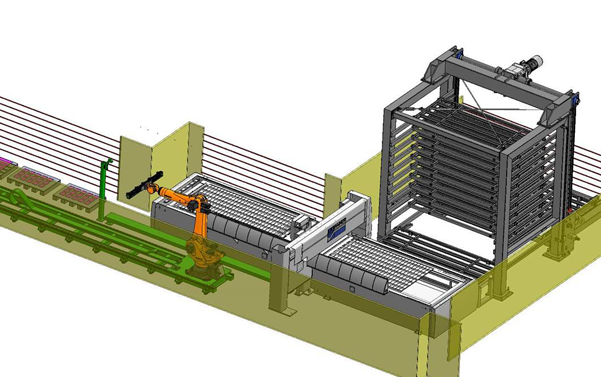

It is used for the laser cutting of product blank materials. According to the production orders, automatic feeding raw materials from the material library, laser cutting, intelligent sorting stacking, waste collection. To achieve the automatic feeding and blanking, intelligent management, save the space, solve the problems of material production management such as failure to monitor in real time, large labor intensity of manual feeding and blanking, low efficiency, and poor security, etc.

The details show

Detailed parameters

Composition

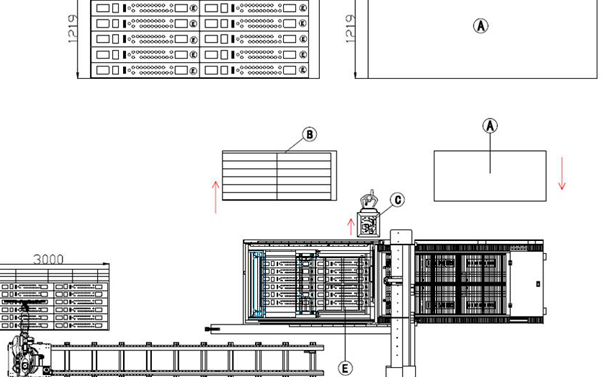

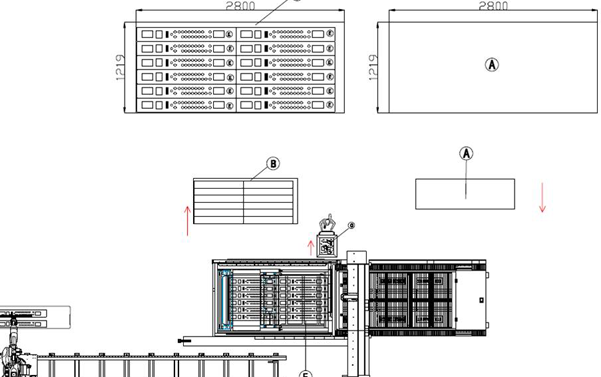

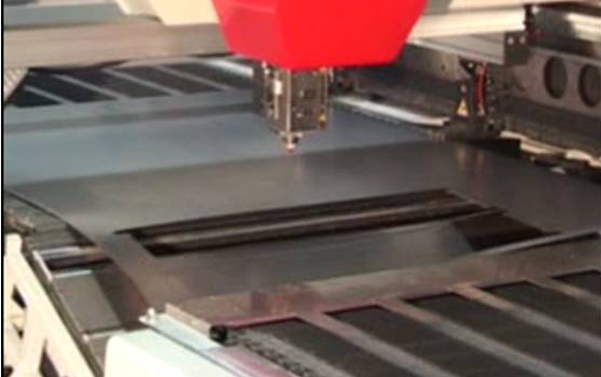

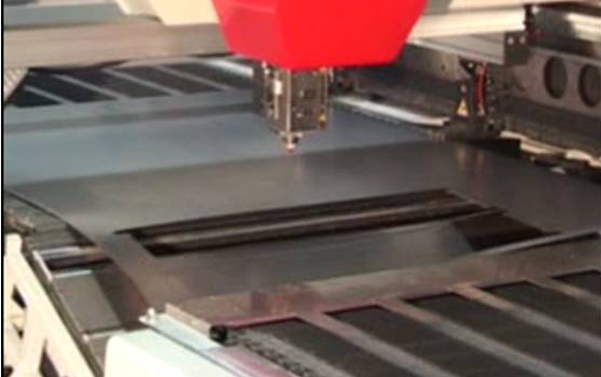

1.Laser one laser cutting host

KW IPG high-speed optical fiber laser-cutting machine

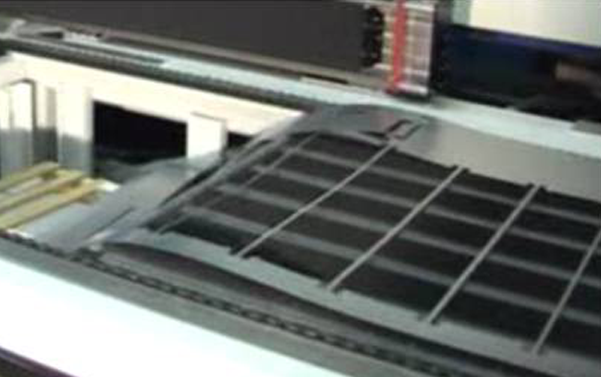

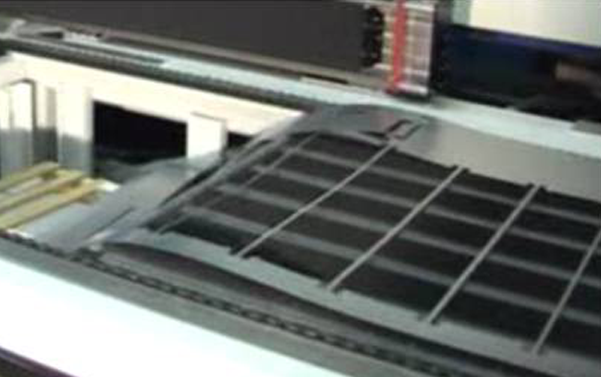

The laser cutting head moves along the horizontal direction (Y axis), and the CNC system controls the feeding clamp plate to move on plate workbench with hairbrush along the longitudinal direction (X axis). The compound motion of the plate and laser cutting head can achieve the real-time sorting and stacking of manipulator as per the procedure of CNC system in the cutting process.Full-automatic discharge door can automatically unload the finished cutting sheet metal.

2.Material library 3000 *1500 *L14

Reasonable usage of space to obtain more production and manufacturing space

Laser cutting and material library via bus control and independent Level II control

Efficient and safe material and production management system

Regular inventory function makes you master the inventory condition at any time

3.Sorting and stacking system of RS16 manipulator finished products

Flexible, rapid and removable Kuka7 axis manipulator

The sheet metal after cutting can conduct the stacking as per the set scheme

Size range for 5 stacking pallets to place work piece: 250*250-600*1500

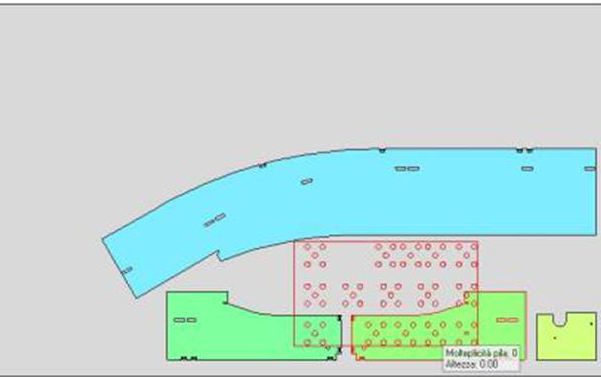

4.Sorting transmission system and CCD visual system of small piece

The laser cutting finished products can be sorted and stacked within the 75*75-250*250 size range.

CCD visual system achieves communication with manipulator by capturing the position of laser cutting finished products to achieve the accurate capturing of work piece by manipulator.

5.Collection of waste material border

The waste material border is collected through the programmable full-automatic discharge door.

Related products

主站蜘蛛池模板: 渝北区| 佛冈县| 根河市| 青神县| 天峨县| 昆山市| 西峡县| 许昌市| 绵竹市| 吴桥县| 前郭尔| 萨迦县| 汨罗市| 吉木萨尔县| 新郑市| 肃宁县| 都安| 樟树市| 土默特左旗| 平阴县| 开阳县| 肥乡县| 锡林郭勒盟| 桂林市| 楚雄市| 水城县| 平湖市| 突泉县| 阳原县| 桐梓县| 定南县| 犍为县| 鲁甸县| 连江县| 佛坪县| 拜城县| 饶河县| 文水县| 杭锦旗| 壤塘县| 武山县|